Control Panel Design, Build, and Testing

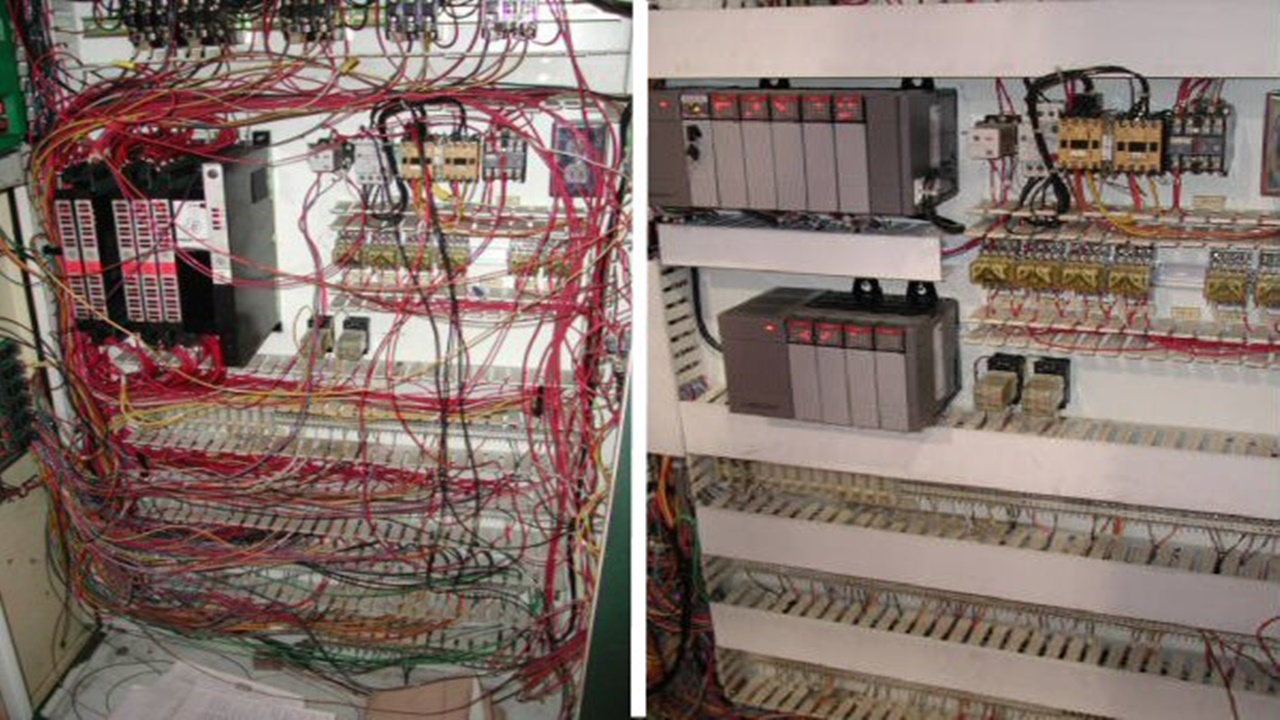

Control panel design is the process of selecting and configuring control components. Relays and timers are two common components, and they simply turn something on or off depending on an input signal. However, more complex control applications may require a programmable logic controller (PLC). This is a microprocessor specially designed for use in industrial settings. To find out how to design and build your custom control panel, read on for more information.

Costs

Control panel building operations allocate costs among the different functions of the system. Materials can run anywhere from thirty-five percent to sixty-five percent. In addition, costs associated with assembly and testing of control panels are usually included in the total cost. Commissioning costs, which involve integrating the completed system with the existing infrastructure, are also included. Here are five factors that affect the costs of control panel building operations. These are typically undocumented changes in the control program or wiring.

Requirements

There are many guidelines and standards for designing, building, and testing a control panel. These must meet specific safety and compliance requirements, such as UL standards and the National Electrical Code. Control panels must also be NEMA environmental-rated and meet the requirements of the arc flash category. A good control panel designer will review the customer’s sequence of operation. Check that all components are in place. He will create schematic drawings to show how wiring is intended to be implemented.

Methods

The pace of change in the field of electrical control panel design is phenomenal. Keeping up with the latest requirements and guidelines can require time, personnel, and resources. Here are some tips to keep up with current state-of-the-art methods. Ensure that your panel meets all required standards by establishing a rigorous control panel testing program. The first step in testing a panel is to review the bill of materials. This document will include requirements for the physical and electrical layout of the panel.

Standards

There are a number of factors to consider when designing a control panel. Failure to meet UL standards can lead to the replacement of the panel by the client, so it’s important that the design is as good as possible. There are several design tips that experts have developed over the years, which are beneficial for anyone trying to design a control panel. A good design will include both electrical and physical requirements. You will need to alternate between the two so that any problems are minimized. You will also need to incorporate schematic drawings and clearance requirements.

Component technologies

The Industrial Controls market is segmented by supervisory control and data acquisition and the components that comprise it. This market includes Programmable Logic Controllers, Distributed Control Systems, Manufacturing Execution Systems (MES), Enterprise Resource Planning (ERP), Human Machine Interface, and other systems. The industrial control panel builders market is expected to grow at a rate of 8% over the next six years. End users for this market include oil and gas, food and beverage, power and utilities, automotive, and more.

Placement

Control panel design and construction should include overcurrent protection. The overcurrent protection device can be placed ahead of the panel enclosure or incorporated in the panel itself. When placing the primary protective device, make sure to keep workers safe. In addition, provide ample illumination and space within the panel enclosure. Components should also be safe to touch. Listed below are some tips to consider during control panel design and construction. This information is available on the Internet.

That’s all about Control Panel Design, Build, and Testing. Hope so, you found this article helpful if you were looking for some brief information about Control Panel Design, Build, and Testing in Automation Industry.

Share your valuable feedback about this post in the comment section. Also, keep visiting the website uptimeauto.com for more updates.