Contact Us

Great things in business are never done one. They're done by a team of people.

Great things in business are never done one. They're done by a team of people.

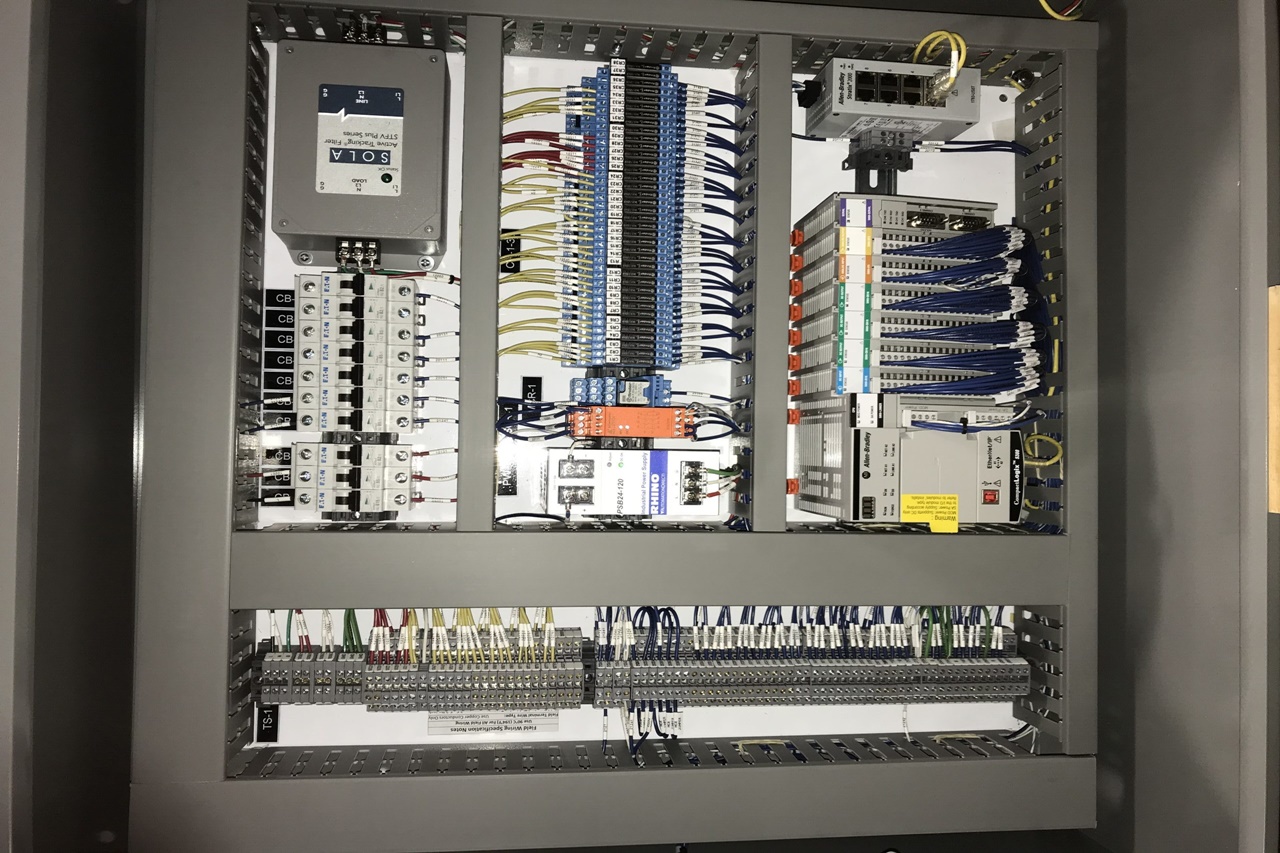

Programmable controllers are at the core of process control. These controllers may be small, dedicated micro or loop controllers, Programmable Logic Controllers (PLC), Programmable Automation Controllers (PAC), or Distributed Control Systems (DCS). Uptime Automation has been successfully implementing programmable controllers since our company’s founding. In fact, we are a leader in the process-control industry, recognized as an authorized System Integrator (SI) by all major industrial programmable controller manufacturers.

Uptime Automation’s success and recognition as a programmable controller system integrator can be attributed to our many years of experience and our proven project methodology that includes:

Adding {{itemName}} to cart

Added {{itemName}} to cart